The ship is buzzing…

- Hotel Operation sends a billion requests to the technical team with issues they want sorted. Renew all galley silicone, increase the temperatures in all dishwashers, change all galley pipes…- Immediately of course.

- Shoreside is pushing for reports and information, to be in compliance.

- Everyone is busy getting their areas, papers and everything else ready…

Preparing for a public health inspection can be a daunting task for all departments on a ship. Especially when the ship is being sent to countries like USA, Canada, Australia, and New Zealand.

While the main focus is often on the hotel operation, the technical department also has to ensure that the ship is in compliance with all public health regulations. This is usually a hectic and exhausting time for all involved, as they also have to manage the daily guest operations.

The infamous cross-connection control program

One of the most time-consuming tasks is ensuring the protection of potable water.

A ship can have hundreds or thousands of connections in the potable water system:

Every sink, every toilet, every shower can potentially thread the potable water system. Every connection in the galley, all the washing machines, the connections to the pools, the sprinkler systems, the black and grey water treatment systems, the food waste systems—

And all those devices need to be regularly inspected and maintained. This can be a challenging task, especially with limited manpower on board.

However, there are ways to prepare in advance and pass the inspection without any issues.

Get ready my brave tech-mates!

- Get your papers straight

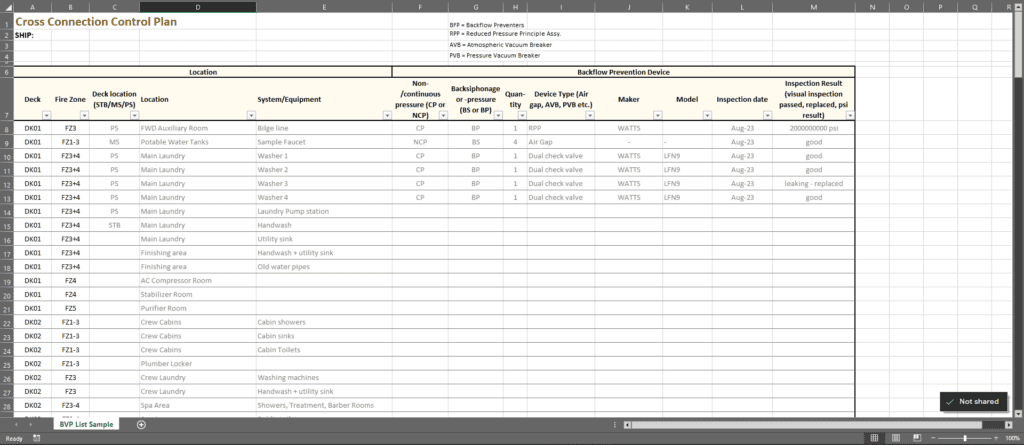

The first step is creating a cross-connection control plan. This document showcases that the ship takes care of its water protection. While setting up the plan for the first time may require a lot of time, it only needs to be updated thereafter. Belo, you find a rough template that can be downloaded and filled with your ship’s data. It is important to continuously update the plan as new locations for backflow preventers will be discovered.

- Have an eye on your connections

Once the plan is in place, the next step is to inspect the backflow devices. As it is difficult to check all the devices within a short period of time, it is best to start early and check them in batches. The excel sheet can be filtered by location. And guess what; you have team mates:

“Get a deck everyone, this week we are hunting backflows, non-returns, air gaps and every connection branching off from the potable water pipes.”

- Test your devices

Yes, some of them need to be tested and logged. But relax, depending on ship size, this should be somewhere between 3-20 devices.

All other suffice with a visual inspection for no leaks and damages.

So make sure you have a testing device on board.

Correction:

Make sure, you have a calibrated testing device on board!!

Or order a service for the testing to be done in port. The device needs to be tested and verified, and the documentation for this should be available on board.

And if you are unsure about how to perform the testing, check out for example Mikey Pipes’ video right here

It isn’t Rocket science. You will manage.

- Be consistent:

From now on, rotate this task throughout the year to ensure that the ship is always ready for inspection.

In conclusion, being prepared in advance is key to passing an inspection without any findings. It is important to continuously update the cross-connection control plan and regularly inspect and test your backflow devices.

Little side note:

I’d be especially interested to know the dimensions of the cross-connection control plan of “Icon of the Seas”. If anyone knows the number of connections, please comment!

Have any additional comments on this topic?

What are your experiences with the testing?

Share your opinion right below the article.

Fair winds to you – Stay safe and enjoy what you do!

Still don’t have a CCCP?

Comments